Why have a large closed field in your desk, when you possibly can have an elegantly minimal open air PC case corresponding to this one? This mini-ITX body case, made out of laser-cut aluminium by Jerome Kelty, nonetheless lets you use a full-size graphics card and ATX energy provide.

Due to our quickly rising PC constructing Fb web page, we’ve seen many customized gaming PCs, from mods based mostly on current case designs to scratch PC builds. You’ll be able to even submit yours for consideration proper right here. Right here we chat to Jerome about how he made this unimaginable open air PC.

: Let’s begin initially. What impressed you to construct this PC?

Jerome: I’ve all the time considered open-chassis designs as being actually attention-grabbing. I simply love the concept of all of the elements being on show and the benefit with which you’ll work on them. Since there aren’t any panels to cowl something up, the elements play a a lot bigger function within the general look.

What had been your necessities for this practice case?

I wished the construct to be actually compact and have a really small footprint. I additionally thought it could be neat if the chassis might be made out of particular person metallic plates that might be bolted collectively, so it might be packaged flat ought to it ever be put into manufacturing. Making the chassis from particular person plates would additionally permit for better ease of customization with out having to revamp the complete chassis.

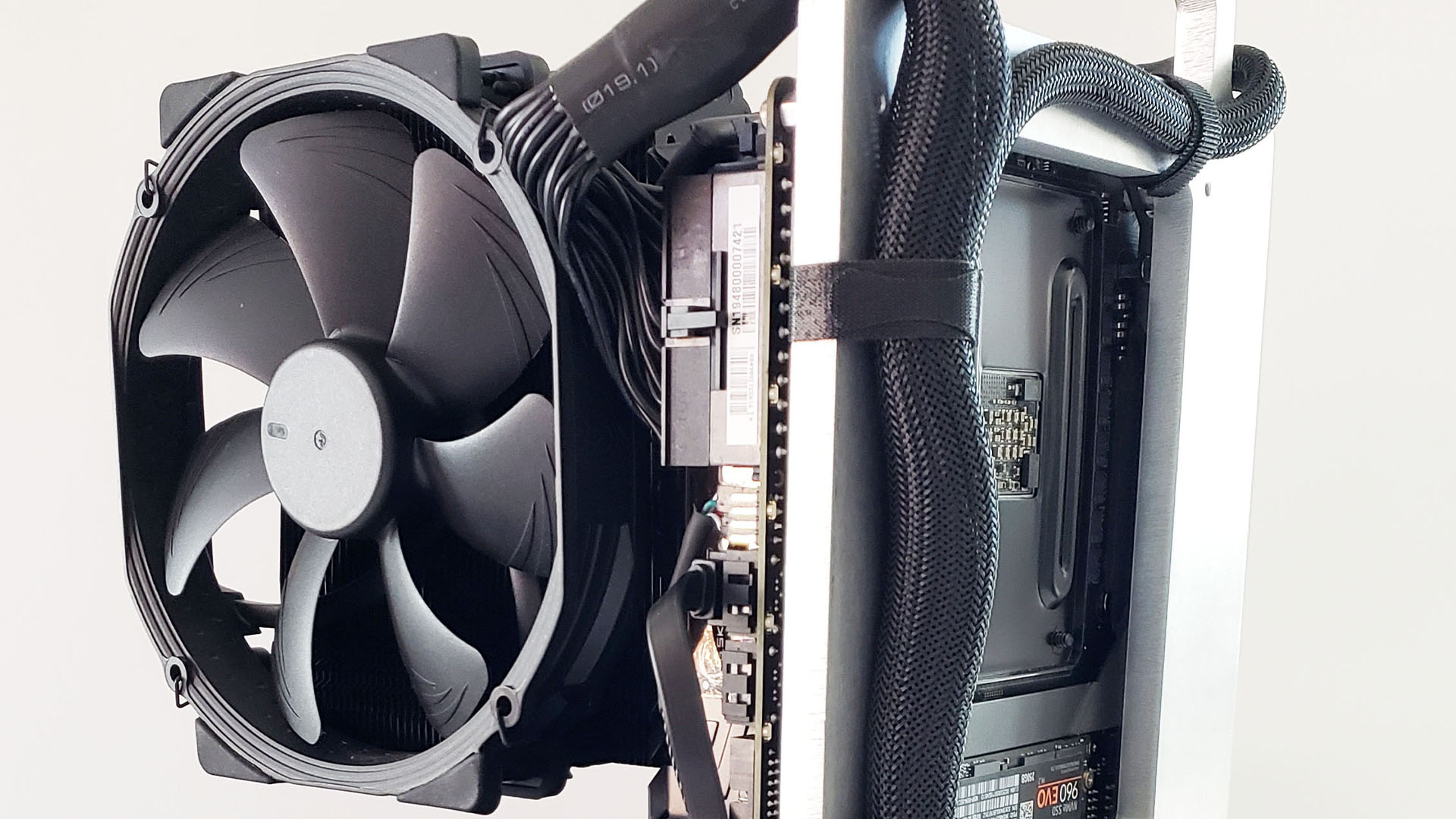

I believed it ought to be capable of accommodate a full-size ATX energy provide and a full-height graphics card with adequate clearance for airflow. I wished to have the ability to use two M.2 drives, together with a 2.5″ drive, and have easy accessibility to the M.2 drive on the again of the motherboard. Simple, clear cable routing was additionally a precedence. I wished the graphics card to suit immediately into the PCIe slot and never have to make use of a riser cable.

I figured that including a deal with on high can be useful for shifting it round, and I additionally added a little bit of area beneath the graphics card so further USB ports might be put in later.

How did you intend and design this construct all through its numerous levels?

I began by laying out the elements on sheets of cardboard, so as to get an thought about how I wished all of the elements to take a seat, and get an thought of the general type issue. Then I took measurements and did drawings of what can be the person flat plates in Inkscape. The Inkscape drawings had been then imported into Fusion360 as SVG information so I might create a 3D mannequin of the chassis.

I downloaded particular person part fashions from GrabCAD, and positioned them within the Fusion360 chassis mannequin to get an thought of the general look of the design. As soon as I used to be proud of that I used to be good to go for fabrication.

How did you get the aluminum items reduce to form?

The three flat metallic plates that make up the chassis are laser reduce from 9.5mm-thick 5052 aluminum by SendCutSend, which is a unbelievable laser-cutting service.

This was positively the best way to go for each price and ease of producing, as I don’t have a CNC router and reducing metallic that thick by hand would have been an infinite quantity of labor. Laser-cutting thick materials does depart a little bit of a tough floor, however since I used to be beginning with a kind of check construct I wasn’t too involved with getting pristine edges – I simply cleaned up all of the sharp edges with a file.

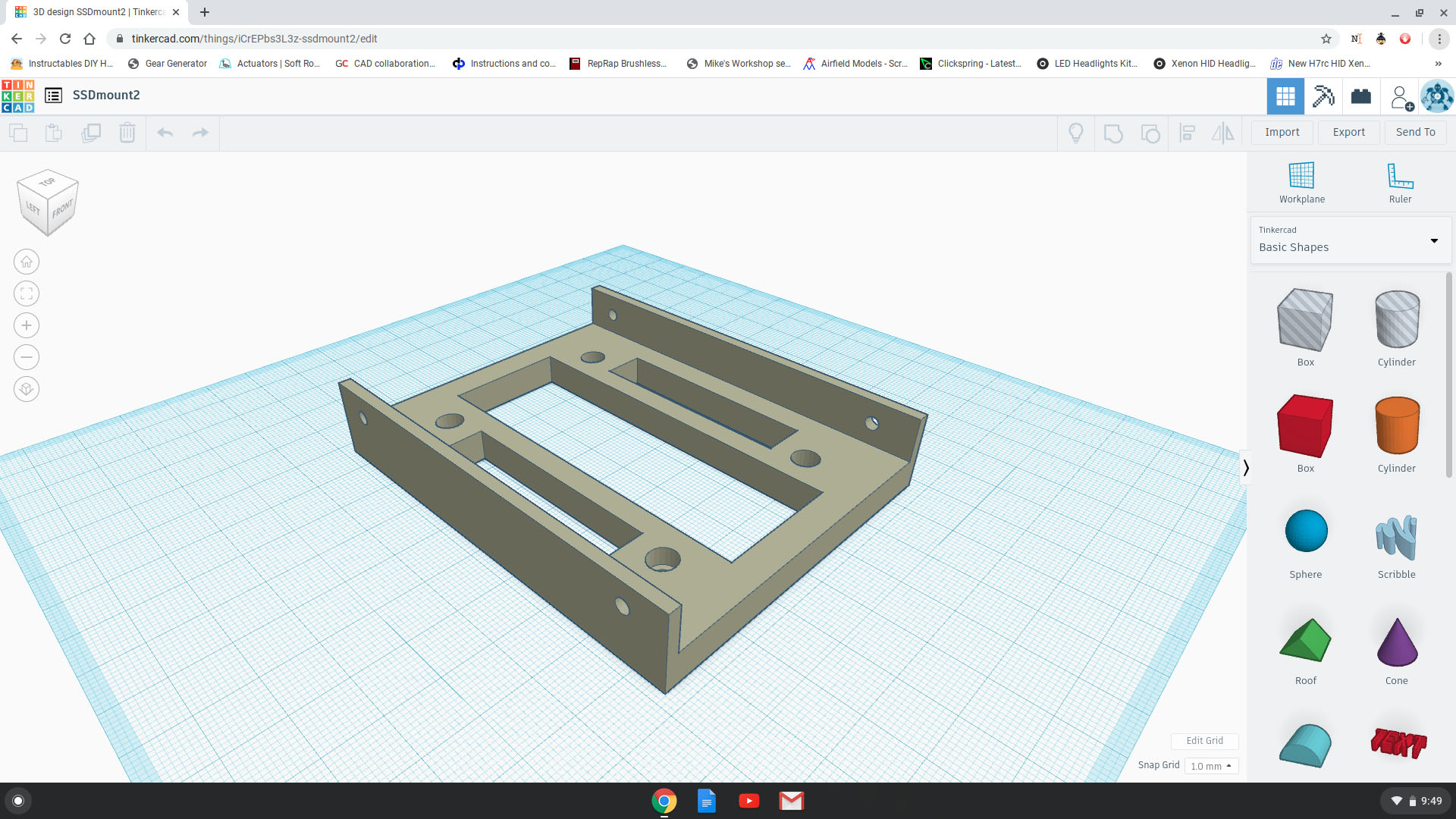

Had been any of the elements 3D printed?

Sure. Printing these elements was the quickest/most economical manner for me to do it given the instruments I needed to work with, so it was actually simply carried out that manner out of necessity. I designed the elements in Tinkercad and printed them in PLA plastic on my previous Printrbot Easy Steel printer.

How does the body match collectively, and the way is your {hardware} mounted to it?

The body is bolted collectively on the edges utilizing socket-head cap screws, and the motherboard is held in place utilizing quick standoffs, identical to a standard PC construct. The two.5″ drive mount is held in place utilizing socket head cap screws. It’s all quite simple actually – it’s super-fast to assemble and take aside.

Is all of it made with precision equipment, or did you employ any hand instruments?

With laser reducing, each time you could have shapes or holes to be reduce out in metallic they should be no less than 50 % of the fabric thickness. This meant I needed to drill and faucet all the threaded holes by hand, so I printed out templates for each the facility provide and motherboard mounting factors. Drilling and tapping all of the holes takes a good bit of labor, however it’s not too dangerous in case you have entry to a drill press.

How did you intend the cable routing?

The cable routing with this design is absolutely simple. It was only a matter of inserting a few cutouts within the chassis plates by means of which cables can move, and leaving a little bit of clearance for the cables to suit between the facility provide and the motherboard mounting plate.

You’ve made the directions for this chassis accessible for anybody to obtain and construct themselves. What is going to they want so as to do that, and what was your motivation for desirous to share your design? How a lot would it not price?

I believed it could be actually neat to share it and see how different individuals might take it and make it their very own. It’s been actually cool to see how different individuals have modified it to go well with their functions and manufacturing strategies. One individual has made it even smaller and 3D-printed the chassis, whereas another person has made it from skinny metal sheet. I believe it’s nice when individuals can take a design after which modify it to go well with their very own supplies, instruments and constructing strategies.

The great thing about this design is that it lends itself to being constructed from all kinds of supplies to go well with virtually any part configuration. Price is relative to the fabric used – it price round $150 for me to have all the thick aluminum plates laser reduce, however it might simply as simply be made in acrylic or an acceptable wooden with only a few small adjustments. If you happen to don’t have entry to a laser reducing or CNC milling service, the design might be modified to be reduce utilizing a band noticed, scroll noticed or jigsaw.

You presently have an air cooler fitted to the CPU, however might or not it’s adjusted to accommodate a closed-loop liquid cooler?

It might simply accommodate a liquid cooling setup. It could simply be a matter of constructing mounts to connect the radiator to the again aspect or fringe of the motherboard plate.

What spec did you select, and why?

My {hardware} necessities had been largely based mostly round doing 3D modeling and CAD work. I wished a mini-ITX motherboard to maintain it as small as potential, and the Gigabyte X570 Aorus Professional WiFi was a stable alternative for the price/options (twin M.2 slots and PCI-E 4 help) and it could give me a little bit of room to develop. I discovered a Ryzen 7 2700 on sale at a unbelievable worth that was too good to move up.

Graphics was a bit trickier as I wished a great, small (beneath 200mm size) 1080p card, and the EVGA GTX 1660 Tremendous actually match the invoice when it comes to efficiency for the value. Mini graphics playing cards had been getting a bit exhausting to search out on the time. I knew I wished to maintain my ATX energy provide, as SFX energy provides had been getting costly on the time and I believed the dimensions and weight of the ATX PSU balanced out the design higher.

Lastly, I simply love the Noctua NH-D15 CPU cooler (I imply what’s to not love?) and thought it could look actually cool having this huge, all-black cooler that’s practically as broad as the entire system. Having all of those similar-width, black elements actually gave the construct a kind of monolithic look that I actually appreciated.

Do you could have any bother with mud ingress?

No bother in any respect and it’s tremendous straightforward to wash. My work space is in my basement and I get little or no mud down there.

Did you come throughout any difficulties?

Probably the most troublesome a part of the construct was drilling a few of the holes within the edges of the aluminum plates. I solved this by performing some attention-grabbing fixturing with a vice in my drill press. Drilling the massive gap for the facility change was a good bit of labor as effectively. I’ve since redesigned the facility provide plate to treatment this, in addition to make it simpler to suit the graphics card.

How heavy is the ultimate system, and is it straightforward to hold?

The naked chassis weight is about 3.5lbs (round 1.6kg), so the completed construct has the same weight to a standard case construct. It’s very stable feeling and tremendous straightforward to hold utilizing the deal with.

How lengthy did it take you to finish this construct, from begin to end?

The entire construct time from begin to end was beneath two weeks.

Is there anything you need to add in regards to the construct course of?

Simply that general it’s a really simple construct that’s straightforward to change. A easy vector drawing program, corresponding to Inkscape or Illustrator, is all you could get elements laser reduce. Additionally, as an alternative of drilling and tapping holes within the edges of the plates, it could be a lot simpler and sooner to chop T-shaped slots to suit conventional threaded nuts – this might permit for development utilizing a a lot wider number of supplies as effectively.

Are you fully proud of the tip consequence, or do you would like you’d carried out a few of it otherwise on reflection?

I’m fairly proud of the way it turned out, however there are positively some elements I’d do otherwise, corresponding to sanding and smoothing all the perimeters and utilizing customized cables to make the wiring look higher. I’d additionally substitute the 3D-printed elements with machined elements. I’ve already redesigned the facility provide plate and altered how the facility button is mounted.

I lately gave my GeForce GTX 1660 Tremendous GPU and ATX energy provide to my son to make use of in his system, and I changed it with a Radeon Professional workstation card and an SFX energy provide, so I believe I’d prefer to revisit it and make it much more compact and cleaner. I’d additionally prefer to construct a water-cooled model that’s extra gaming oriented.

Open body mini-ITX PC specs

- CPU: AMD Ryzen 7 2700

- GPU: EVGA GeForce GTX 1660 Tremendous

- Storage: Samsung 960 Evo 250GB, Sabrent Rocket 512GB, ADATA 2.5in SU800 1TB

- Reminiscence: Initially G.Ability Flare X 16GB CL16 DDR4 3200MHz, however I’ve now modified it to Essential Ballistix 32GB CL16 DDR4 3200MHz

- Motherboard: Gigabyte X570 Aorus Professional WiFi

- PSU: EVGA B3 450W modular

- Cooling: Noctua NH-D15

This can be a good piece of minimal design Jerome – it simply reveals what kind of PC energy you may get right into a tiny footprint in the event you’re ready to depart your laptop open to the weather. We additionally love the truth that you’ve made the design information freely downloadable for anybody else to have a go.

This submit initially appeared on Customized PC, which has been protecting superb setups for over 20 years and is now a part of . Be a part of our practically 500k member Fb group to debate this construct.

If you happen to take into account your self to be an skilled PC builder, you possibly can submit your personal customized PC construct to us in the present day for an opportunity of being featured on sooner or later.